Can self-healing concrete provide the solution?

Bangladesh is in the midst of a remarkable urban transformation. From the capital of Dhaka to emerging cityscapes across the nation, construction is the drumbeat of progress. Yet, this rapid growth comes with a significant challenge: the durability of our infrastructure. Concrete, the backbone of the modern world. Over time, small cracks caused by environmental stress, heavy loads, and chemical exposure can widen, allowing water to seep in and wear down the steel reinforcement within. This leads to costly repairs, reduced structural lifespan, and potential safety hazards. For a nation building its future, this is a critical vulnerability.

Concrete that heals itself

Imagine a material that can heal its own wounds, much like human skin. Such is the promise of self-healing concrete. It is a game-changing innovation that redefines construction. The technology works in two primary ways. The first is autogenous healing, a natural but limited ability of unhydrated cement to react with water and seal very fine cracks.

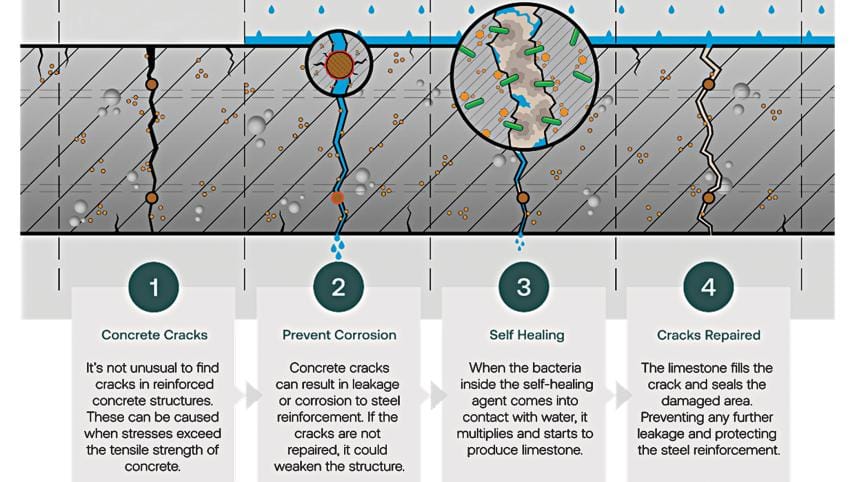

The more advanced method is autonomous healing. The most promising approach involves embedding specific dormant bacteria within the concrete mix along with their food source (often calcium lactate). When a crack forms and water enters, the bacteria is awaken. They consume the nutrients and, through their metabolic process, produce calcium carbonate, also known as limestone. This meticulously fills the crack, sealing the damage and restoring the concrete's integrity. This autonomous repair system can seal cracks up to 0.8mm wide, preventing water ingress and stopping small problems from becoming major structural failures.

Sensicon, a partner of Basilisk, a Dutch startup that specialises in the development of self-healing concrete solutions for infrastructure projects, produces a self-healing concrete, Sensicrete. The product was invented by Henk Jonkers, a microbiologist and professor at Delft University of Technology. It can be used in any concrete structure that is susceptible to water or moisture exposure, for example, concrete tunnels and sea defence walls. Sensicrete is made from a standard concrete mix with a self-healing agent added to it. The agent contains a dormant bacterium; once cracks appear and the bacteria come into contact with water, they produce limestone and seal the cracks. The exact healing process is shown below.

Extending Lifespan

By autonomously repairing cracks, the concrete prevents water, chemicals, and salts from penetrating the structure.This stops the corrosion of internal steel reinforcement.The result is a significantly extended lifespan for buildings, bridges, and other infrastructure. In fact, structures built with self-healing concrete require far fewer repairs and less ongoing maintenance over their lifetime. While the initial material cost may be higher, the long-term savings from eliminating expensive manual crack injections and repairs are substantial.

Waterproofing and Enhanced Safety

The self-healing process makes the concrete inherently waterproof. As cracks seal themselves, they prevent water from passing through. For structures like basements, tunnels, and water tanks, expensive and labour-intensive waterproof coatings or membranes often become unnecessary. This not only saves on initial construction costs but also removes a potential point of failure, as membranes can tear or degrade over time. Some advanced self-healing composites are designed to be more flexible than traditional concrete. It allows them to bend slightly under stress before fracturing.

Projects Using Self-Healing Technology

While the technology is still gaining widespread adoption, it has been successfully demonstrated in several high-impact projects globally. Construction company Heijmans Infra used self-healing concrete to build a pilot project, a railway underpass in Rijen, the Netherlands, for the first time. In this pilot project, construction company Heijmans used self-healing concrete to build a railway underpass wall in the Netherlands. The key innovation was using the concrete's ability to automatically repair its own cracks to justify a major design change, they successfully reduced the amount of horizontal steel reinforcement by 35%.

The concept of self-healing concrete is relatively new and is still under research in most parts of the world, including the UK. But there have been many successful trials of this new technology in laboratories as well as real-world applications. Basilisk has successfully used self-healing concrete in several commercial projects. For example, they extended the lifespan of a bus lane by 15 years using their product, Basilisk Liquid Repair System ER7. Situated in Schiphol Airport, the bus lane was showing a large number of cracks along the entire route. As of now, there are no large-scale public projects documented in Bangladesh.

The Bangladeshi Context

The drive for smarter construction materials is already taking root in Bangladesh. Academic institutions are exploring innovative solutions tailored to local needs. Moreover, the Housing and Building Research Institute (HBRI), has long been a pioneer in researching and promoting alternative and sustainable construction materials. Their work in areas like eco-friendly blocks sets a crucial precedent for adopting next-generation technologies like self-healing concrete, aligning with the national goal of building sustainable and affordable housing.

A Wiser Investment for the Future

Although self-healing concrete has a higher initial cost, its long-term economic and environmental benefits are significant.

By dramatically reducing the need for maintenance and repairs, it extends a structure's lifespan, making it a more cost-effective solution over time. This extended life also lowers the demand for new cement production, a major source of CO2 emissions, thereby reducing the material's overall carbon footprint.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments