Building smart for a cooler Bangladesh

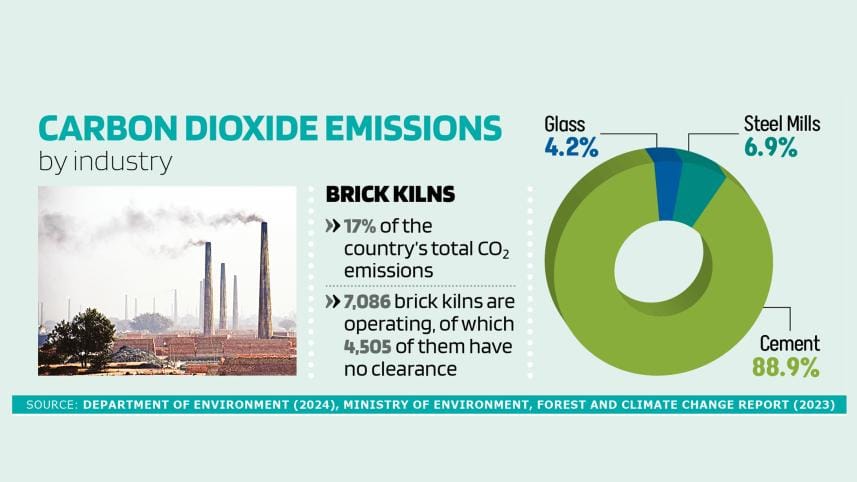

Carbon footprint is the total greenhouse gas emissions caused by an activity or sector. It is a key measure of environmental impact, especially under climate change. Bangladesh's footprint is about 124.793 million tonnes of CO₂ as of 2023. Md Abu Sadeque, Executive Director of Centre of House Building and Research (HBRC) stated to the Daily Star that roughly one-third of Bangladesh's emissions come from construction and building materials, so transforming this sector is essential for meeting climate goals.

A large part of this comes from materials that form the base of development such as bricks, cement, and steel. Bangladesh has pledged to cut 84.92 million tonnes of CO₂ by 2035 in the NDC 3.0 . The investment needed to achieve this is about US$116.8 billion. The plan divides responsibility: 26.7 million tonnes of CO₂ reductions will come from domestic efforts, while 58.2 million tonnes will depend on international finance, technology, and partnerships. These numbers highlight both ambition and the scale of support needed. If this single sector changes how it builds, the nation can move much closer to its climate goals while improving air quality and health.

Low-Carbon Materials That Work

Traditional fired bricks are one of Bangladesh's largest polluters. Each kilogram of brick emits around 300 grams of CO₂, while concrete blocks emit only 100 grams. A simple switch could reduce two-thirds of current brick-related emissions.

Engineers and builders are already turning to alternatives. Compressed Stabilized Earth Blocks (CSEB), interlocking blocks, hollow concrete blocks, aerated concrete, and ferro-cement panels all provide durable, low-carbon options.

Modern techniques such as geopolymer cement, rapid-hardening cement, and bamboo composites can cut construction emissions by 40 to 50 percent compared to conventional methods.

In flood-prone areas, the innovation is even more striking. A recent project named "Amphibious house" was built with sun-dried mud blocks float when water rises, avoiding kiln-fired bricks altogether. These ideas show that sustainable building can be practical, affordable, and climate-smart.

Local Materials, Local Gains

One quick win is replacing high-carbon materials with greener alternatives. Engineer S.M. Khorshed Alam, president of the Bangladesh Association of Construction Industry, urges moving away from fired bricks toward options such as compressed stabilized earth blocks, interlocking CSEB, hollow concrete blocks, thermal blocks, aerated concrete and ferro-cement panels. A recent project like "Swapner Bari- the amphibious house" for floods use sun-dried mud blocks instead of kiln-fired bricks, cutting embodied emissions. Innovations like geopolymer (non-Portland) cement, rapid-hardening binders and bamboo composites can lower construction and housing emissions by roughly forty to fifty percent. Local sourcing also matters a lot. Because Bangladesh imports crushed stone aggregate, locally produced compacted earth blocks and ferro-cement panels reduce transport emissions and costs. Reusing waste materials in mixes further shrinks the carbon footprint. In short, switching materials through proven alternatives, recycled inputs and local manufacture is one of the fastest and most scalable ways to cut construction emissions.

Waste Reduction and Recycling

Another lever is waste management. Construction and demolition generate huge waste streams worldwide, and Bangladesh is no exception. Allowing demolition debris, scrap steel and leftover concrete to be recycled in new projects can cut demand for new cement and steel, saving energy and emissions. Experts call for "life-cycle analysis" in project planning: building longer-lasting structures may cost more upfront but pays off by avoiding future rebuilds. Professor A.F.M. Saiful Amin of the Department of Civil Engineering, BUET points out that a growing recycling industry could fundamentally change construction: "Gradually, many recycling industries will develop to recycle polymers, steel, bricks and concrete and to help grow recycling-based startups. These businesses will transform the construction sector by reducing its carbon footprint." Bangladesh has only just begun to incorporate demolition-reuse policies, but researchers and industry leaders agree this could be a big opportunity to trim the sector's emissions without sacrificing growth.

Policies and Partnerships for Change

Beyond individual projects, government action is key. Bangladesh has started introducing rules to favor green construction. For example, a recent amendment to the Brick Kiln Act now bans the use of toxic topsoil and firewood in brick-making, effectively phasing out the dirtiest kilns. The forthcoming building code and incentives from regulators will further shift the market. Development banks and donors are also engaged with several international grants that support workshops for masons on alternative bricks and link producers with finance.

The construction industry in Bangladesh holds great potential to shrink the nation's carbon footprint. From using low-carbon materials and better insulation to recycling waste and enforcing green standards, every step can make a difference. Sustainable construction is not only good for the planet but essential for people: only by becoming more environmentally conscious in all aspects of building can future generations continue to enjoy life as we were able to once. With bold measures and cooperation across government, builders and financiers Bangladesh can indeed build its future brick by brick, and leave a much smaller carbon footprint.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments