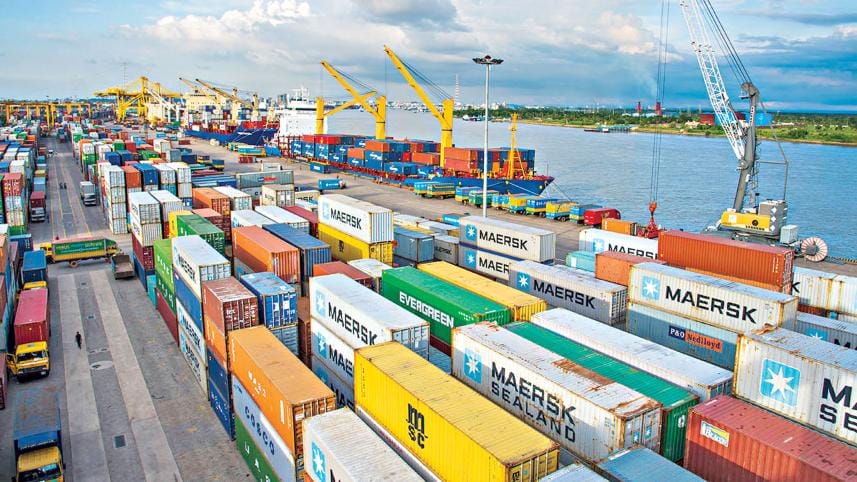

Can Bangladesh take advantage of digitised supply chains?

CAN BANGLADESH TAKE ADVANTAGE OF DIGITISED SUPPLY CHAINS?

Ongoing geopolitical tensions, trade disputes between major economies, climate change-related disruptions, and rapid changes in consumer preferences collectively pose a complex set of issues for the global supply chain, impacting operational efficiency, financial performance, and the ability to adapt to changing market conditions. In a PWC study, 46% of 4000 CEOs surveyed confirmed that they are concerned about the disruptions in their supply chains due to recent geopolitical conflict, while 78% predict climate risks will impact their supply chains over the next 12 months. Complex supply chains with a series of largely discrete and siloed processes from product development, manufacturing, and distribution of the product have resulted in vulnerable supply chains. For a fully integrated supply chain that is visible, resilient, and agile managers need to adopt more comprehensive digital approaches.

Bangladesh government is now in pursuit of the "Digital Bangladesh to Smart Bangladesh: The road to 2041" vision. Under the vision, the government is encouraging business supply chains to adopt digital technologies and contribute towards achieving national sustainable development goals.

A digitally transformed supply chain provides real-time visibility into its members, allowing managers to identify gaps that may cause disruptions and address them. McKinsey research found that on average companies that aggressively digitize their supply chains can expect to boost annual growth of earnings before interest and taxes by 3.2 percent and annual revenue growth by 2.3 percent. Hence it is expected that investments in digital technologies represent a growing percentage of organizations' IT budgets. Global digital technology (DT) spending is expected to reach nearly USD 3.9 trillion in 2027 with a five-year compound annual growth rate (CAGR) of 16.1%. Asia/Pacific region will account for a 33.5% share of worldwide DT spending, according to the International Data Corporation. With the young and growing population in the Asia/Pacific region that is more tech-savvy than older generations, rapid infrastructure developments towards urbanization are driving the demand for digital offerings both in products and services. Bangladesh is no exception to DT adoptions.

Bangladesh has been able to achieve an inspiring level of success in bringing digital revolution through the Digital Bangladesh Vision, declared by Sheikh Hasina's government on December 12, 2008. Since then, the software and hardware sector has created 20 lakh employment opportunities and has earned USD 1.4 billion from exports, which was only USD 26 million in 2008. To continue with the remarkable progress Bangladesh government is now in pursuit of the "Digital Bangladesh to Smart Bangladesh: The road to 2041" vision. Under the vision, the government is encouraging business supply chains to adopt digital technologies and contribute towards achieving national sustainable development goals. Industries such as agriculture, ready-made garments, and pharmaceuticals among others, are crucial for Bangladesh's strategic sovereignty. Hence it is important to examine how DT can be adopted in these industries.

AGRICULTURE, FISHERIES, AND FOREST

In FY 2020-21, agriculture, livestock, fisheries, and forest products accounted for about 12.5% of Bangladesh's total GDP and employed approximately 40% of the total population, according to the Bangladesh Bureau of Statistics. Currently, farmers can meet the domestic demand for main staples such as rice. However, the self-sufficiency situation might not last longer because of decreasing arable land, frequent natural disasters, and population growth. Generally, the outcome of the practices addressing climate change issues can only be seen in the long term. So, adapting to the new climatic conditions through the uptake of technologies is a viable solution. Bangladesh should closely follow global adaptation technologies emphasising agricultural mechanisation and the use of ICT in farming. Farming decisions driven by data will help in fighting back against climate change. For example: satellites in the sky and sensors in the field will be able to detect nutrients and water in the soil and assist in making decisions regarding nutrition to be used.

READY-MADE GARMENTS

The readymade garment industry is Bangladesh's principal export earner with a value of over USD 46.9 billion in export earnings in FY2022-23. However, the industry faces regular criticism regarding worker safety, operational efficiency, management's unfair labor practices, and its environmental footprint. Cutting-edge computer vision technology assists in tracking workers' movements and understanding their activities thus ensuring the safety of workers in real-time. By analyzing video streams, the AI system detects potentially hazardous behaviors, such as operating machinery without proper safety gear or lifting heavy objects incorrectly thus fostering a safer and more productive work environment. Moreover, the implementation of block chain technology would enable to tracing of the details of the product origins, the conditions in which they are produced, and the carbon footprint of the garment in a complex apparel supply chain.

PHARMACEUTICAL

Bangladesh is the only least developed country (LDC) that meets nearly 98 percent of its domestic demand for pharmaceutical products, with a market size of approximately USD 3 billion. In addition, Bangladeshi pharmaceutical products are exported to approximately 150 countries and generated $169 million in fiscal year 2020-21. The promising growth of the pharmaceutical industry in Bangladesh is threatened by the drug adulteration. Some estimates suggest that the flow of fake medicine in the open market at any time could be around 2,500 crore taka making up 30% of all medicines sold. Internet of Things (IoT) and block chain can play a major role in collecting, sensing, and recording information from the environment and transferring that data over a network without human interaction. These technologies would enable pharmaceutical companies to track their medicine during the entire journey from labs to consumers. This would improve drug safety, making sure of a verifiable provenance of who delivers what to whom, when, and where.

As evident in all the three major industry sectors successful supply chain DT requires organizations to deploy Industrial Revolution 4.0 related technologies across all supply chain members. However, a recent McKinsey study found that the average supply chain has a digitization level of 43%. Only 2% of the surveyed executives said the supply chain is the focus of their digital strategies.

Having the right, digital-savvy leaders who can translate their business needs into relevant digital applications and who encourage employees to experiment with new technologies is key to successful digitally transformed supply chains. It requires significant reskilling of existing employees and developing skills among graduate students. Globally, in-house training is considered the most popular method of developing competencies amongst supply chain professionals. Meanwhile, universities along with peak industry bodies should design new curricula that include supply chain digitalisation aspects.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments