Local cable makers now of international calibre

Eastern Cables Limited, a subsidiary of the Bangladesh Steel and Engineering Corporation, was once the only cable manufacturer in Bangladesh.

The company, which became a state-owned enterprise following the Liberation War, was established in Chattogram's Patenga in 1967 to manufacture pipes and other goods.

New governments usually patronise heavy or non-heavy industries at the beginning stage, and Bangladesh was no exception.

But in due time, local entrepreneurs came forward to invest in cable manufacturing in the late 80s, when the sector was mostly dependent on imports for setting up transmission lines and household wiring.

Eventually, brands such as Paradise, BBS, BRB, Partex, SQ, Transcom Cables Ltd, RR Kabel, and Bizli emerged in the cable market as the entrepreneurs understood its business potential considering how the whole country would have power coverage in the future.

With this backdrop, they utilised innovation to overcome various challenges and became devoted to developing the cable manufacturing industry.

The public sector needs power transmission and distribution networks through overhead cables while the private sector needs it for households and industries.

"The entrepreneurs had far sight and were innovative, and realised the future of the industry. So, some of them took the initiative to manufacture cables and cater to domestic demand," said A.K.M. Ahasanul Haque, chief operating officer of Partex Cables Ltd.

The companies then started making new high quality products to fulfil the country's requirement for electrical and communication cables.

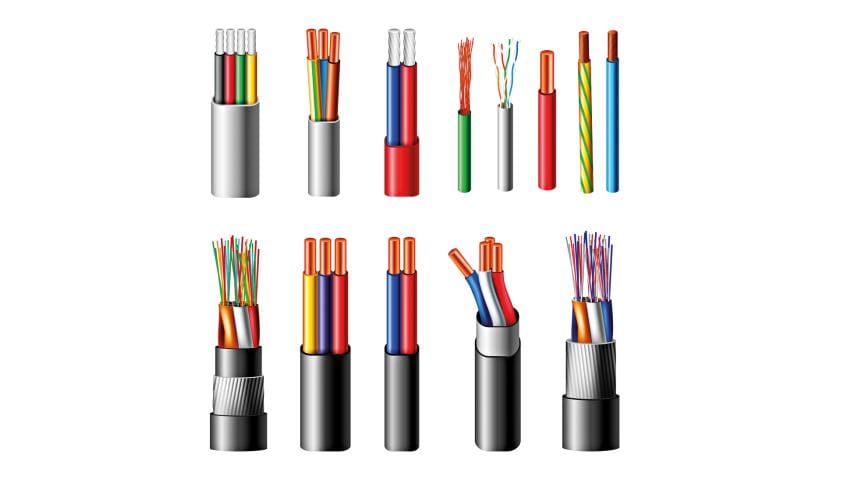

For example, the industry started with household wires and now manufacturers underground cables, marine cables, extra high voltage cables and more.

"Now, the industry manufactures 33kv capacity extra high voltage cables while earlier they could make up to 11kv capacity cables," Haque said.

"In this consideration the local companies developed their capacity and engaged their innovative ideas to contribute to the economy," he added.

High-voltage cables, which include a conductor and insulation, are used for electric power transmission at high voltage.

However, there are substandard cables currently in the market.

"So, the government should do a market drive to remove substandard products and create awareness among consumers as it is an issue of safety," Haque said.

He then said the government is prioritising power generation but does not give importance to ensuring quality power supply for households and the industrial sector.

"If the government realise the necessity of quality power supply, the entire cable industry would benefit," he added.

An industry insider said there are more than 150 small, medium and big cable manufacturers in the market, which is lead by BRB with a 41 percent share followed by Eastern with 15 percent, BBS 13 percent, Paradise, Partex and Bizli 6.5 percent each, and SQ 5.3 percent.

Other players collectively account for 22.2 percent of the market.

However, only 8 to 10 of these companies provide international standard products.

Local manufacturers produce almost all kinds of cables, including communication cables, telephone wires, LAN cables, fibre optic cables, house wiring, extra high voltage cables, telecommunication cables and marine cables.

Of them, only Partex, BRB, and BBS manufacture underground cables that provide extra safety.

Haque then said the private sector consumes 70 percent of the market while the rest 30 percent goes to the public sector.

Rafiqul Islam Rony, director of marketing and sales at BRB Cable Industries Limited, credited the government and entrepreneurs for developing the sector as the former took initiatives to generate power while the latter came forward to cater to the demand.

He also said the sector has helped develop skilled manpower and generate employment.

Rony then suggested the government provide support to local companies to reduce imports as they have built up the capacity to manufacture international standard cables.

Cable manufacturers are currently dependent on raw material imports from Chile, China, India, Oman, Malaysia, South Korea and Singapore.

"Local players would have thrived more had they gotten the big contracts of the Bangladesh Power Development Board and Rural Electrification Board, which go to Chinese vendors thanks to their lower offers," he said.

The government is now emphasising on quality transmission and distribution to reduce the system loss. For this reason, the government has been purchasing cables from local manufacturers, which has helped the industry grow in the past decade, Rony added.

Rakib Ahmed, head of marketing at Bizli Cables, a subsidiary of Pran-RFL Group, said the industry is growing due to the expansion of power grids across the country in the last six years.

He then thanked the entrepreneurs for catering to the cable demand and thereby saving foreign exchange in line with the government's initiative for developing the power sector.

Bangladesh Steel Re-Rolling Mills (BSRM) introduced a new construction cable called "Low Relaxation Prestressed Steel Strand (LRPC strand)" in a bid to cater to the Tk 3,000 crore market segment that is currently dominated by imports.

The country's leading steel maker invested a total of around Tk 1,000 crore to establish an LRPC strand manufacturing unit under its new concern, BSRM Wires.

The LRPC strands are used in the prestressing of concrete for different kinds of construction work.

LRPC strands are used in pre-stressed concrete girders for building roads, flyovers, river and railway bridges, prestressed concrete domes, hollow core slabs, steel beams and TT slabs, silos, hangars, aqueducts and viaducts, as well as railway sleepers.

There are currently a number of bridges, flyovers, and tunnels under construction where LRPC strands are being used.

Tapan Sengupta, deputy managing director of BSRM, said the product is a new addition for the cable industry even though it is considered a construction material.

The industrialists also alleged that the Chinese companies who implement grid line projects use substandard products to save costs, which is not possible for local companies that work with quality cables.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments