Fabric for our buildings: A possibility

Ashikur Rahman Joarder and Kaniz Sultana Sathi

Fabric structures, now a mature building technology, are usually considered as a temporary structural system for covering large column-free spans. Due to improvements in materials, structural analyses and environmental control, the method can also be considered for permanent buildings. This technology with unique properties that make it useful for certain applications offers an important alternative to conventional construction.Background

Fabric buildings have been around a long time from the tents of the middle-east to the tepees of the Native Americans to the canopy on the coliseum in ancient Rome. In the industrial age, the use of tensile structures for engineering purposes goes back to the old suspension bridges first built in the early 1800s; not until 1952 was the idea converted into a roof structure. The two major families of architectural membranes are PVC-coated polyester fabric and Teflon-coated fibreglass membrane. Teflon-coated fibreglass was first used by NASA for the Apollo spacesuits in the 1960s after the Apollo 1 disaster. The first permanent architectural application of Teflon-coated membranes for buildings came in 1972 on the University of La Verne campus in Los Angeles. Applications since then include the Haj Terminal in Jeddah, Saudi Arabia, completed in 1982, which provides 105 acres of shading for pilgrims to Mecca; the San Diego Convention Centre; the Georgia Dome in Atlanta; and Reliant Stadium in Houston, which has a retractable roof covered by a high-translucency membrane and a natural turf field. The Technology

Designing Tension Fabric Membrane Structures Designing even simple fabric structures to perform under a variety of load conditions can be a complex task. Each component is both visible and structural, and relies on all other components to function property. Determining the Form

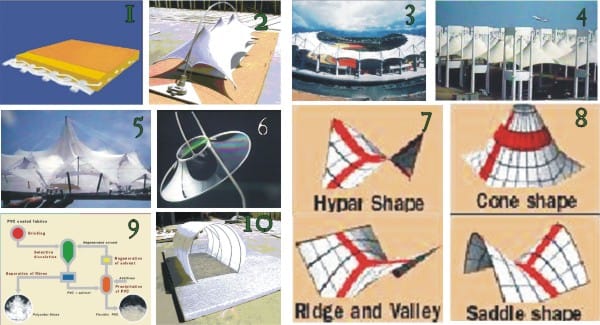

The first step in designing a tension fabric structure is to create a form with double curvature and sufficient pre-stress. The second step is to determine the boundaries of the tensioned fabric. Once the primary points have been determined, the next step is 'form finding'. There are two methods of form finding: physical modelling and computer aided design. Physical Models: During design development, tension fabric structures can be visualized with a physical model. Models are either created using soap films or by stretching nylon over wire frames. Working with physical models enables one to view the structure from any angle. Computer Aided Design: Computer software not only helps create a 3D model, but can also determine the amount of fabric, how it should be cut, the size and length of the structural members and the hardware the project will need. The designer is also able to modify the shape more easily than with physical models. Shapes of fabric structure

The inverted double curvature is associated with textile architecture; it enables a wide variety of shapes - Cone shape: The cone shape that can cover square or round surfaces or surfaces with many angles.

- Horse saddle shape: The horse saddle shape is the development of rectangular plane surfaces.

- Hyper shape: For the hyper (hyperbolic parabolic) shape, the inverted curves follow diagonals of a square or rectangular base.

- Ridge and valley shape: The ridge and valley shape is the development of plane, square or rectangular surfaces.

Description of material

Layers of Fabric: Fabric is used as a building material in a coated form, a flexible composite material. It consists of three principal layers. - High tenacity polyester base cloth.

- Flame retardant plasticized coating.

- High performance polymer surface treatment.

Fireproofing of Fabric

Fabrics are self-extinguishing, do not propagate flames, and do not generate flaming drops. Fabrics have a specific behaviour under fire. The weld seams automatically open as soon as temperature exceeds 100°C allowing smoke to escape from the textile building. If a pile of boards make up the furnace inside the box, because of the heat, the flames slowly spread on the fabric; and gases and smoke escape through the opening in the roof of the tent. The flames on the fabric automatically extinguish themselves, when the heat is no longer sufficient to support the fire. Only the fire in the wooden box continues to burn. After the test, (see figure) the seams have opened because of the elevated temperature and the hole made by the fire. Environmental aspect of fabric structure

Lighting of fabric structure Due to the translucency of most membrane materials, tensile structures can allow large quantities of light to penetrate the building skin. However, it is not just the quantity of light that affects the perception of space, but also its quantity. Therefore the use of light in tensile architecture requires careful consideration. - Daylight: structural foils and fabrics act like a lampshade for daylight.

- Additional direct light sources: Transparent surfaces can be incorporated in the design of a membrane roof to bring directional daylight into a space.

Recycling of fabric

For pure, uncoated fabrics and also some toils, a full recycling process is possible. But when used for membrane structures, fabrics are usually coated. As yet, they cannot be fully recycled, but have to be shredded and then added to the coating compound when new membranes are produced. Use of fabric

- As temporary event structure

- As permanent double membrane roof

Adaptability

Adaptable to different climates

A well designed fabric structure can be adapted to all types of weather conditions in all latitudes. - Desert areas: It is used in the Grand Canyon (Colorado), where the temperature rises above 50 C (125 F) and winds above 160 km/h (100 mph) are recorded on a regular basis.

- Cold areas: In Kazakhstan, a fabric building is subjected to extreme climate conditions. Winds above 140 km/h (90 mph) are recorded on a regular basis. It snows 150 days a year with temperatures below - 40 C.

- Sea-side areas: Built on the New Zealand coast, fabric structure resists storm winds and salty mists. Temperatures can exceed 40 C (106 F).

- Tropical areas: The Kuching stadium in Malays is located in a tropical area and is subjected to high temperatures and violent winds. The humidity level is very high with yearly precipitation exceeding 3830 mm.

Possible applications - Applications for fabric structures include the semi permanent and temporary fabric-and-frame structures applied to agricultural, greenhouse, and storage uses.

- Improved materials have allowed use of these structures for waste treatment facilities, tennis courts, and pool facilities.

- More elaborate configurations, curved in plan and section, serve as outdoor concert halls, enclosed sports facilities, and atrium spaces for larger structures such as office buildings, medical facilities, shopping malls, airports, exhibitions, international sports meet, ware house, factory extension, site office, show room, disaster relief centre, military shelter, restaurant and many other applications.

Fabric structures are not a substitute for conventional construction, but their unique qualities enable them to perform certain building tasks very efficiently. In general, special performance requirements, such as the need for long spans or for natural lighting, encourage the use of this building system. General features

- Quick installation: 1000 m2 in eight hours with eight men.

- Clear span: no obstructing pillars up to 40 meter width.

- Modular and Extendable: enable expansion with ease, length in multiples of 5.0 meter.

- Cost effective: competitively priced, compared with conventional buildings.

- Replaceable: save costs and ideal for project sites.

- Easy maintenance: practically maintenance free.

- Wind speed specification: 120 km / hr.

- Snow load: 20 kg/m2.

- Flame retardant standard: BS 5438, DIN 4102.

Boundless possibilities

Tensile membrane structures are becoming the choice for the future because of its technical, economical and ecological features. They are: - Resistant to extremes of temperature,

- Excellent construction properties,

- Customized properties to meet specific requirements,

- Non-flammable, UV-resistant, opaque to transparent, self-cleaning, etc,

- Long-life,

- Acoustic optimizations,

- Recyclable,

- Ecologically efficient use of materials,

- High level of pre-fabrication,

- Low transport and storage costs.

Fabric in architecture school

School: Dept. Of Architecture, Bangladesh University Of Engineering and Technology, Dhaka. Project of the students of Architecture, BUET based on fabric structures including a successful true-scale interpretation, reflects the interest on the structural system among the learners and adaptability of fabric in different climatic regions including tropical areas. There is immense possibility of using this material in Bangladesh. Presently, its unavailability and limitation of technical knowledge are practical hindrances. In this period of globalization, there should be no hesitation to welcome advanced building materials. At the same time our architects and researchers should go for new building materials that are most suitable and appropriate in our socio-economic and cultural context. We can undertake research and development with local materials (e.g. jute) to compose fabric and resolve the structural system, which will be suitable for our environment, demonstrate higher performance, require shorter erection time and shall be greater value for money. The endless creative possibilities of membrane structures give a wonderful opportunity to communicate vision, freedom of expression, to make individual or corporate statement, the unique possibility to make free flowing shapes, to integrate with other materials, to contrast transparency and opacity and to challenge the senses. Ashikur Rahman Joarder, Lecturer, Dept. of Architecture, Bangladesh University of Engineering and Technology, Dhaka

Kaniz Sultana Sathi, Lecturer, Dept. of Architecture, AIUB, Dhaka.

|

01) Layers of Fabric 02) Designed by Faisal Billah Maruf 04) Haj Terminal in Jeddah, Saudi Arabia 05) Nylon model 06) Soap film model 09) RECYCLING PROCESS 10) Designed by Azmaeri Nusrat Shoma |